Our Craft – The Blueprint of a Custom Inflatable Boat Manufacturer

True quality is built in, not bolted on. Our process focuses on four cornerstones of manufacturing excellence to ensure every boat we make is built to last.

High‑Pressure Drop‑Stitch Construction

We engineer drop-stitch inflatable boats using thousands of polyester threads between waterproof PVC layers.

This high-pressure structure (6–20 PSI) delivers the rigidity and efficiency necessary for premium custom inflatable kayak manufacturing and inflatable boat OEM applications.

Learn more about drop‑stitch construction and PVC/TPU coating from the comprehensive overview on Wikipedia.

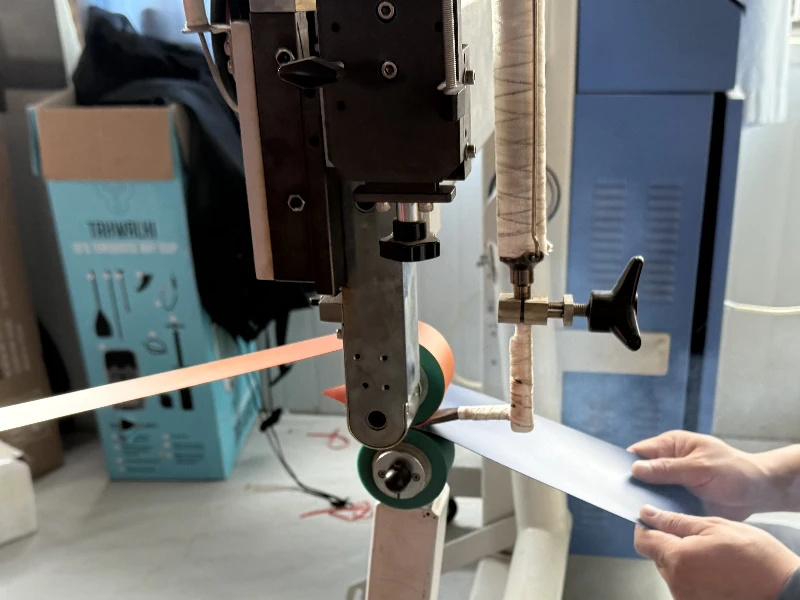

Heat‑Fusion Sealing

We apply precision heat-fusion sealing to weld the drop-stitch core with PVC layers. This technique ensures airtight strength ideal for any custom inflatable watercraft manufacturer seeking durability and performance.

The result is an ultra-tight, durable hull ideal for custom inflatable boat markets and inflatable kayak OEM clients.

Learn how heat‑fusion sealing bonds drop‑stitch cores to reinforced PVC for ultra‑rigid inflatable structures — as explained by Aquaglide.

High‑Frequency (RF) Welding of PVC Seams

To ensure airtight and tear-resistant seams, we use high-frequency (RF) welding, which utilizes 27.12 MHz electromagnetic energy to heat PVC at the molecular level—creating seals as strong as the base material itself.

RF welding minimizes heat distortion and avoids adhesives, preserving material integrity

Rigorous 24-Hour Inflation Test

Before leaving our facility, every single boat is inflated to its full working pressure for a 24-hour lockdown test.

This critical quality gate verifies the absolute integrity of all seams and valves, guaranteeing your boat arrives perfectly airtight and ready for action right out of the box.

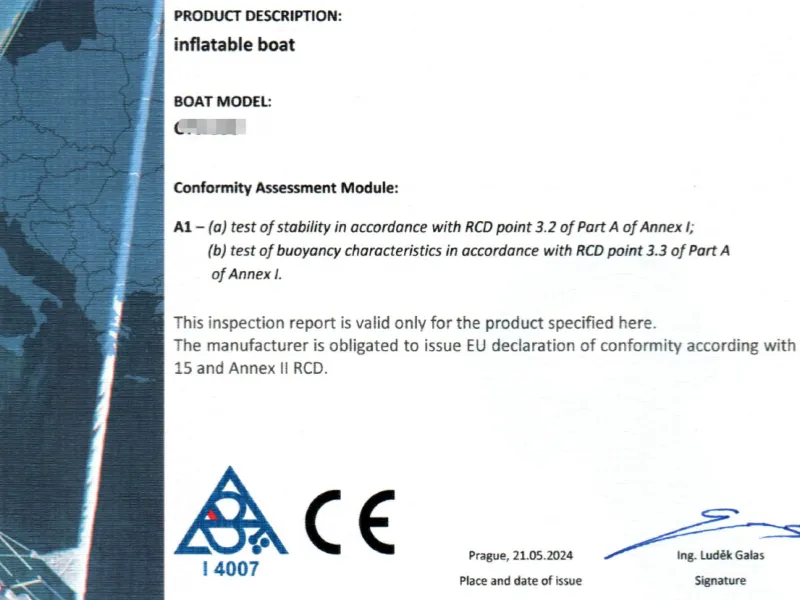

Verified Quality, Guaranteed Performance

At Blue Rafty, we don’t just build inflatable boats — we certify their performance. Every vessel undergoes rigorous testing and meets international standards to ensure reliability in real-world conditions.

International Certifications & Industry Standards

CE Marking – Our boat is CE certified under the EU Recreational Craft Directive 2013/53/EU, verifying it meets rigorous European standards for construction, safety, and design.

Final Quality Gate: Pressure & Leak Validation

Our quality protocol mandates a final PSI Leak & Pressure Endurance Test, where each boat must hold its full recommended pressure for 24 hours to verify absolute airtight integrity.

Ready to Discover Our Craft in Action?

Whether you’re looking to stock your retail stores with our “Blue Rafty” line or launch your own private-label brand, our quality-first manufacturing process is your strategic advantage.

Let’s discuss how our capabilities can meet your goals.